INPUT

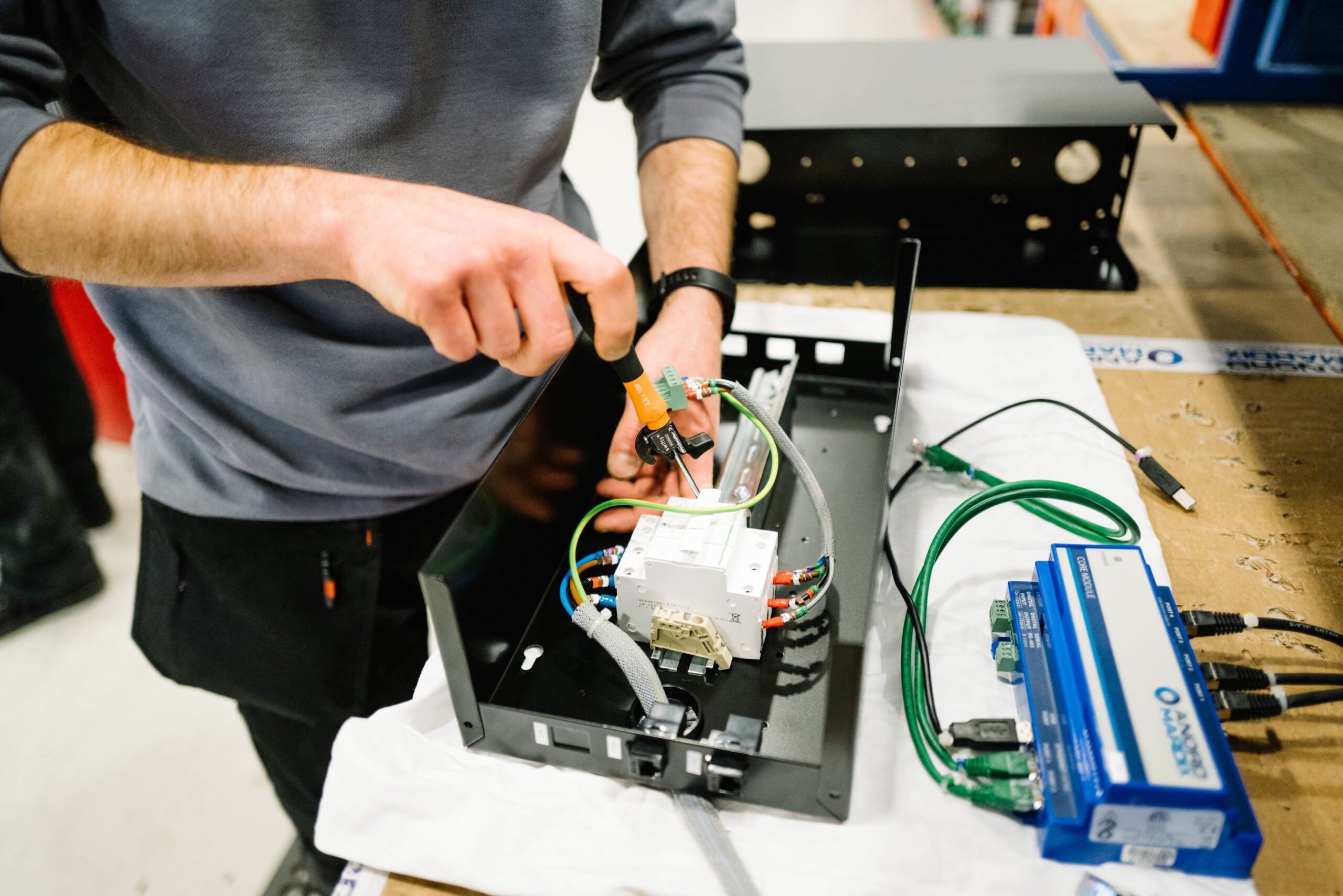

Input power (standard) 90-277 VAC (480 VAC 4W+G) 50/ 60 Hz

Input power (enhanced) 480-600 VAC (3W or 4W+G) 50/ 60 Hz

Voltage connection terminals 22 – 14mm/sq.

Overload protection Internally fused

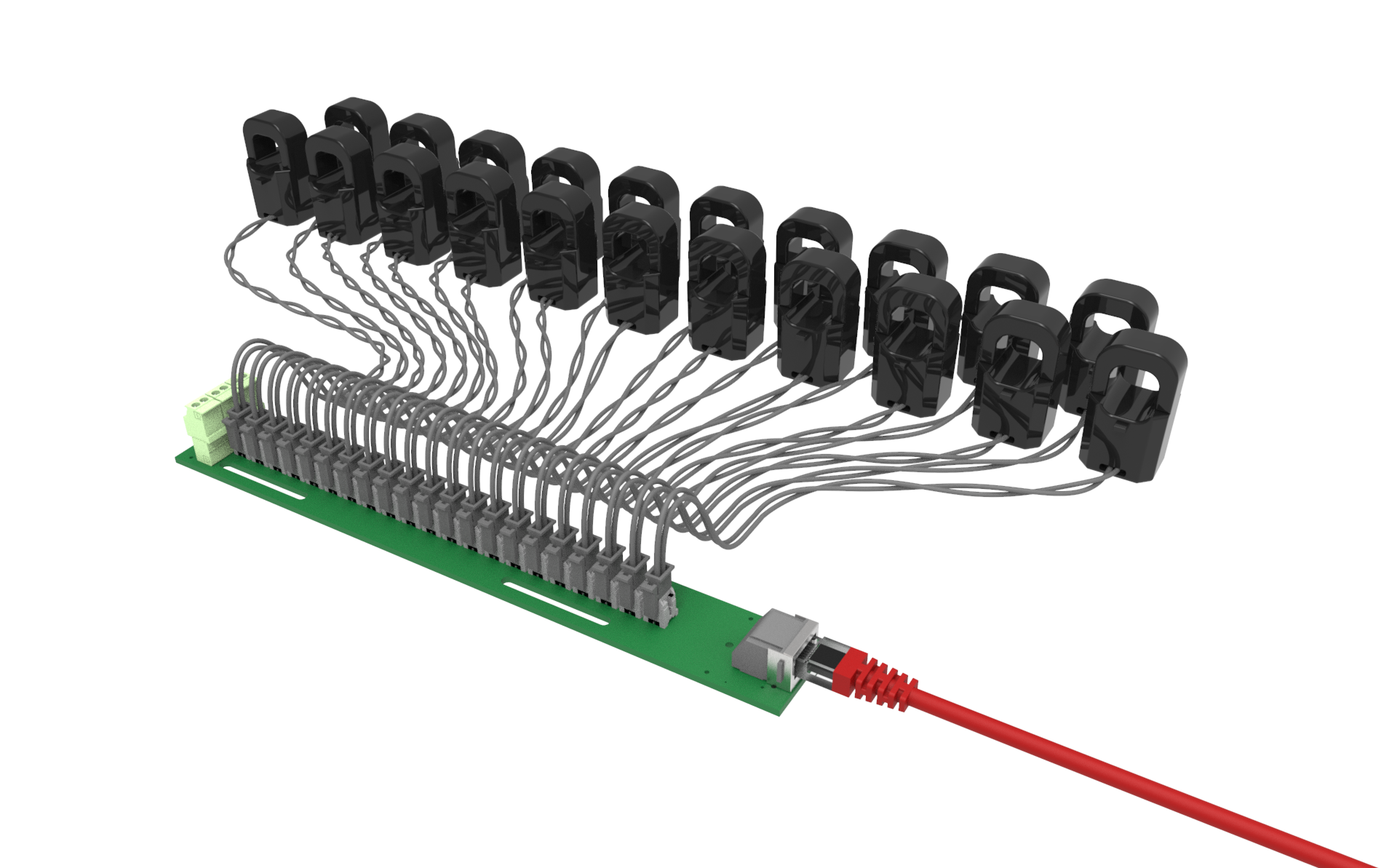

Power consumption <5W / 0.1 A @ 240 VAC Channels / circuit capacity 24 x 4 channels (96 circuits total) PERFORMANCE Accuracy 0.50% Sampling rate > 3 kHz

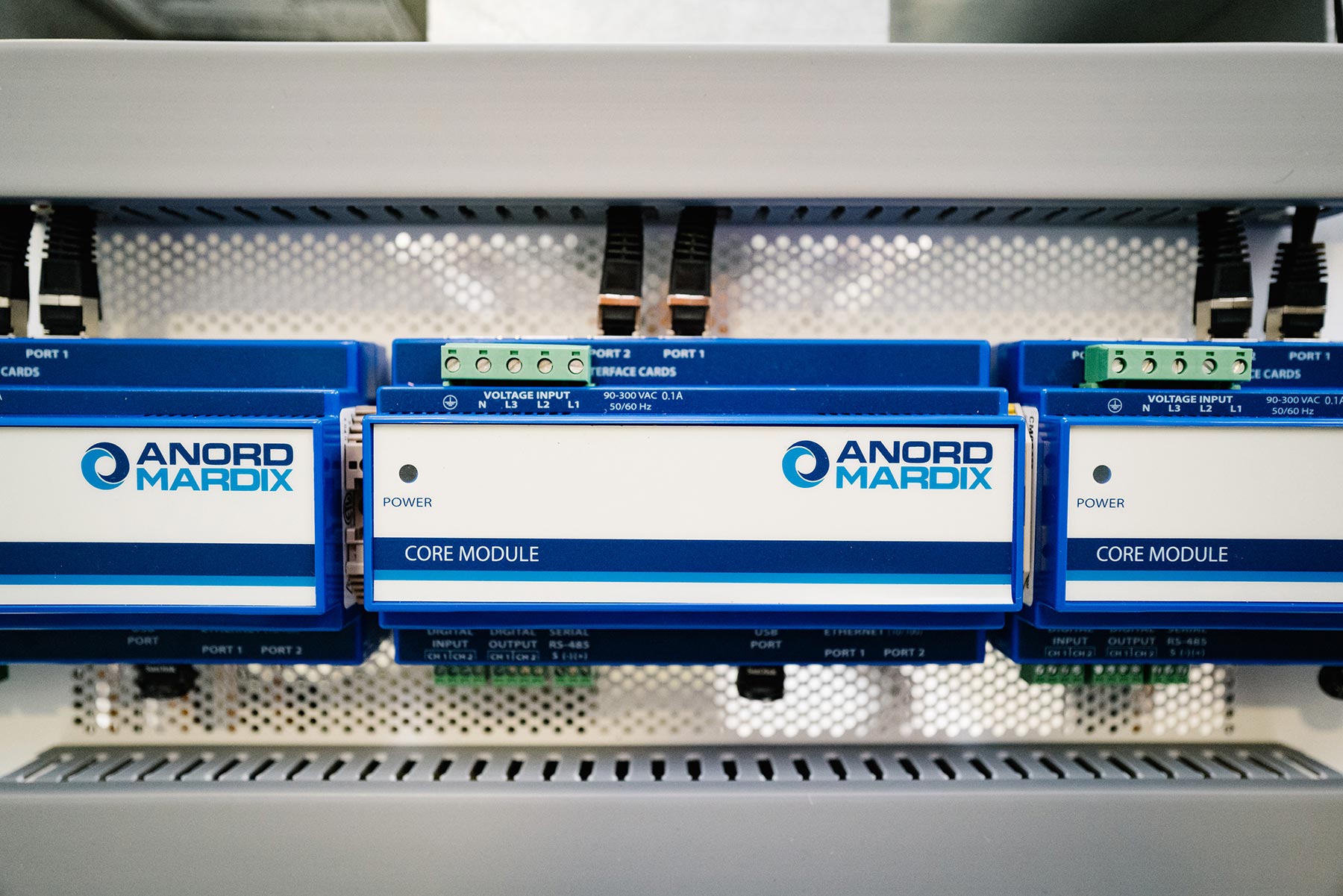

COMMUNICATIONS

Data protocols Modbus TCP/IP (Ethernet), Modbus RTU (RS-485 2 wire), HTML (web server), SNMP and BACnet.

Modbus serial specifications 9600, 19200, 38400 Baud (selectable)

Ethernet ports 2 x RJ-45 10/100 Mbit

USB port USB 2.0 Type A

Web server HTML via standard browser

WiFi option 802.11 g/n ; requires WiFi option

ENVIRONMENTAL

Operating temperature 0 to 60 °C (32 to 140 °F) (<95% RH non-condensing)

Storage temperature -40 to 70 °C (-40 to 158 °F)

Enclosure versions NEMA 1/IP20 (indoor use); NEMA 4 / IP67 (outdoor use)

APPROVALS

Agency approvals UL Listed to EN61010-1, Cat. III, pollution degree 2, CE